Categories

-

Advertising / Agriculture / Apparel & Clothing

-

Architecture / Art & Craft / Automobiles

-

Bags & Shoes Accessories / Spare Parts / Books & Stationery

-

Business Services / Mobile Accessories / Computers & Laptops

-

Construction / Contractors & Freelancers / Education & Training

-

Electronics / Engineering / Environment

-

Event Planner / Fashion & Beauty / Financial

-

Gifts & Toys / Handicrafts / Health Care

-

Home Appliances / Hotel & Restaurants / Industrial Chemicals

-

Machinery Equipment / Information Technology / Jewelry

-

Kitchen / Instruments / Leather

-

Packaging / Personal / Plastic Products

-

Recruitment / Rental / Restaurants & Beverages

-

Security / Telecommunication / Tour & Travels

-

Transportation / Wooden Furniture

Used Oil Analysis - Trending Analysis

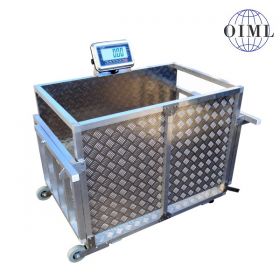

Business Services - Business Support Services-

*******530

Show

- Supplier: N/A

- Price: INR 2500.00

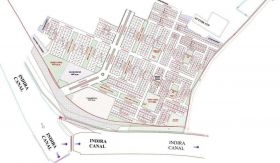

- Navi Mumbai View on Map

- Add to Favourite

get multiple quotes

get multiple quotes